باب المنيوم & نافذة عملية الإنتاج

خطوة 1

التصميم والرسم

تحليل احتياجات العملاء: تحديد حجم الباب/النافذة, أسلوب, وآلية الفتح بناءً على متطلبات العملاء.

الخلق الرسم: تنتج رسومات تصميم دقيقة لضمان الدقة.

الخلق الرسم: تنتج رسومات تصميم دقيقة لضمان الدقة.

خطوة 2

إعداد المواد

الألومنيوم: استخدم الألومنيوم 6063-T5 من أجل مقاومة القوة والتآكل.

خيارات الزجاج: عرض خفف, العزل, منخفضة, وأنواع زجاجية أخرى.

ملحقات الأجهزة: مفصلات عالية الجودة, أقفال, مقابض, وختم شرائط.

خيارات الزجاج: عرض خفف, العزل, منخفضة, وأنواع زجاجية أخرى.

ملحقات الأجهزة: مفصلات عالية الجودة, أقفال, مقابض, وختم شرائط.

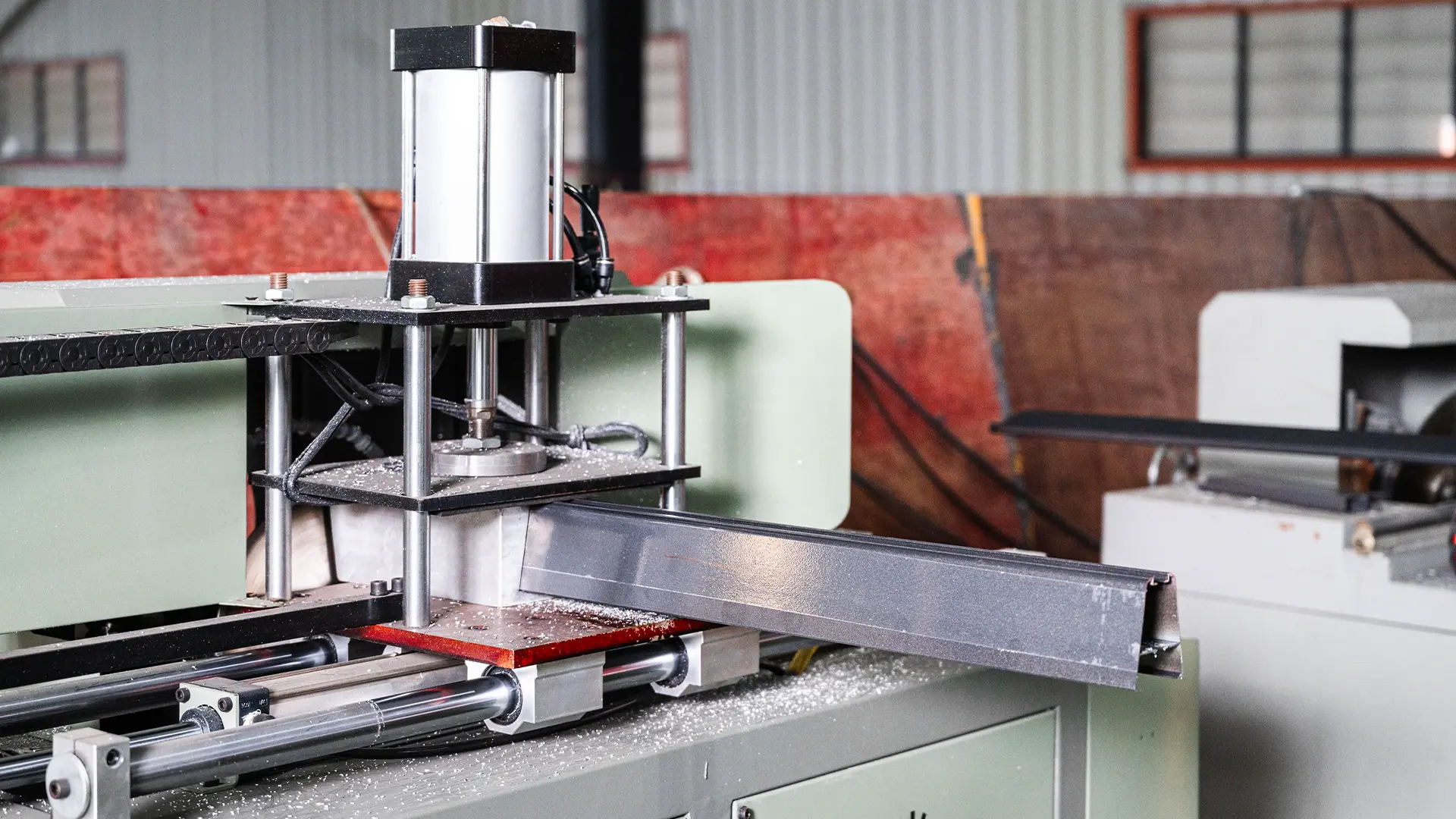

خطوة 3

معالجة الملف الشخصي

قطع: استخدم آلات CNC لخفض الملفات الشخصية لتصميم المواصفات.

اللكم: قم بإنشاء ثقوب في ملفات تعريف لتثبيت الأجهزة.

الطحن: تشكيل ملفات تعريف لتحقيق تصميمات هياكل محددة.

اللكم: قم بإنشاء ثقوب في ملفات تعريف لتثبيت الأجهزة.

الطحن: تشكيل ملفات تعريف لتحقيق تصميمات هياكل محددة.

خطوة 4

معالجة الزجاج

قطع: قطع الزجاج لمطابقة أبعاد الباب/النافذة.

طحن الحافة: حواف زجاجية ناعمة للسلامة والانتهاء.

تقع: تعزيز الزجاج لتحسين السلامة إذا لزم الأمر.

طحن الحافة: حواف زجاجية ناعمة للسلامة والانتهاء.

تقع: تعزيز الزجاج لتحسين السلامة إذا لزم الأمر.

خطوة 5

حَشد

تجميع الإطار: قم بتوصيل ملفات التعريف باستخدام موصلات الزاوية لتشكيل إطارات.

التثبيت الزجاجي: قم بتناسب الزجاج في إطارات مع شرائح الختم.

تثبيت الأجهزة: نعلق المفصلات, أقفال, والمقابض.

التثبيت الزجاجي: قم بتناسب الزجاج في إطارات مع شرائح الختم.

تثبيت الأجهزة: نعلق المفصلات, أقفال, والمقابض.

خطوة 6

ضبط الجودة

فحص المظهر: تأكد من أن الأسطح خالية من العيوب والألوان متسقة.

دقة الأبعاد: تحقق من أن الأبعاد تتطابق مع مواصفات التصميم.

اختبار الوظيفة: اختبار فتح/إغلاق المرونة وأداء الختم.

دقة الأبعاد: تحقق من أن الأبعاد تتطابق مع مواصفات التصميم.

اختبار الوظيفة: اختبار فتح/إغلاق المرونة وأداء الختم.

عملية مراقبة الجودة: ضمان التميز في كل التفاصيل

من المواد الخام إلى المنتجات النهائية, نحن ننفذ عملية مراقبة جودة متعددة المراحل لضمان تلبية كل الباب والنافذة أعلى المعايير.

من خلال عمليات التفتيش الدقيقة والشيكات الصارمة, نحن نوفر آمنة, متينة, وجمالا الأبواب والنوافذ لعملائنا.

01

فحص المواد الخام

- ملامح الألومنيوم: تحقق من تكوين السبائك والمعالجة السطحية لضمان مقاومة القوة والتآكل.

- لوحات: فحص التشوه, تشققات, نَسِيج, وعيوب مثل تلف الحشرات أو الانحلال.

- زجاج: فحص الخدوش, فقاعات, والانحرافات الأبعاد.

ملحقات الأجهزة: تحقق من المواد, الانتهاء من السطح, والوظائف لضمان عدم وجود صدأ أو تشوه.

02

فحص عملية الإنتاج

- دقة الأبعاد: استخدم أدوات الدقة لقياس الأبعاد, ضمان الانحرافات ضمن التسامح.

- جودة التجميع: فحص ضيق المفصل, دقة تثبيت الأجهزة, والتشغيل السلس.

- تناسق العملية: تحقق من أن كل خطوة تلبي متطلبات العملية القياسية, ضمان اتساق الإنتاج.

03

فحص المنتج النهائي

- فحص المظهر: فحص جودة السطح, لون, لمعان, والتسطيح لضمان عدم وجود عيوب.

فحص الوظيفة: اختبار فتح/إغلاق المرونة, وظائف قفل, وسلاسة الأجهزة. - اختبار الختم: فحص أداء الختم لضمان عزل الصوت والعزل الحراري تلبي المعايير.

جودة مستدامة

استخدام مواد صديقة للبيئة من الموردين من الدرجة الأولى لضمان معايير الجودة الدولية وتقليل التأثير البيئي.

إنتاج الدقة

مصنعنا المتكامل, مجهزة بتكنولوجيا متقدمة, يضمن الإنتاج الفعال والتسليم الدقيق للمشاريع واسعة النطاق.

دعم دورة كاملة

من استشارة التصميم إلى دعم ما بعد البيع, نحن نقدم حلولًا واحدة لضمان تجربة سلسة لعملائنا.

القيمة المباشرة

الإنتاج المباشر من مصنعنا الداخلي يلغي الوسطاء, تقديم حلول فعالة من حيث التكلفة ومخصصة.