एल्यूमीनियम दरवाजे & विंडोज विनिर्माण

एल्यूमिनियम दरवाजा & खिड़की उत्पादन प्रक्रिया

डिजाइन और ड्राइंग

आरेखण: सटीकता सुनिश्चित करने के लिए सटीक डिजाइन चित्र का उत्पादन करें.

सामग्री तैयारी

कांच के विकल्प: स्वभाव की पेशकश करें, इंसुलेटिंग, कम-ई, और अन्य कांच के प्रकार.

हार्डवेयर ऐसेसोरिज: उच्च गुणवत्ता वाले टिका, ताले, संभालती है, और सीलिंग स्ट्रिप्स.

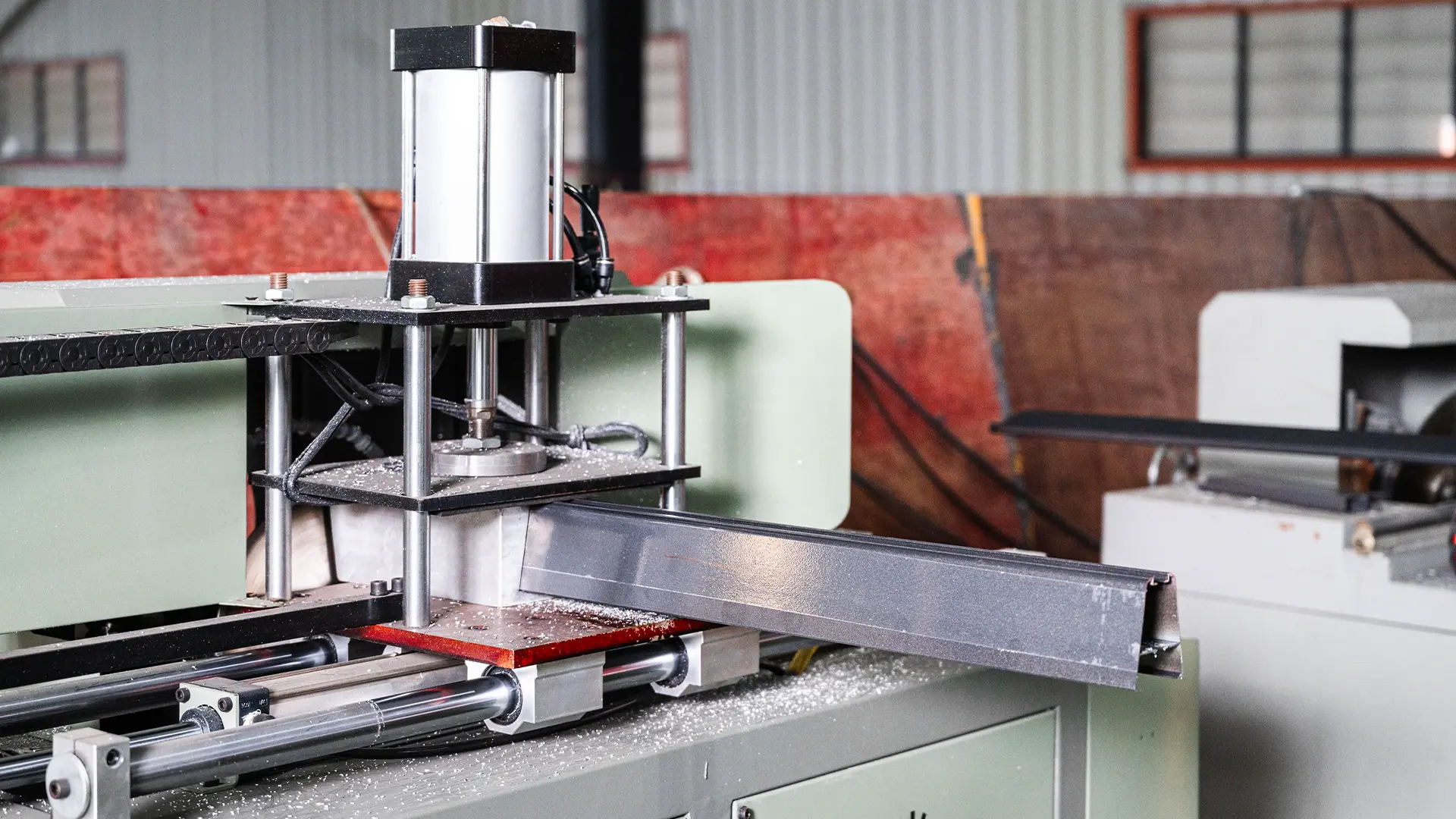

प्रोफ़ाइल प्रसंस्करण

छिद्रण: हार्डवेयर इंस्टॉलेशन के लिए प्रोफाइल में छेद बनाएं.

पिसाई: विशिष्ट डिजाइन और संरचनाओं को प्राप्त करने के लिए आकार प्रोफाइल.

ग्लास प्रक्रमन

बढ़त पीसना: सुरक्षा और खत्म के लिए चिकनी कांच के किनारों.

टेम्परिंग: यदि आवश्यक हो तो बढ़ी हुई सुरक्षा के लिए कांच को मजबूत करें.

विधानसभा

ग्लास इंस्टॉलेशन: सील स्ट्रिप्स के साथ फ्रेम में ग्लास फिट.

हार्डवेयर इंस्टॉल करना: टिका संलग्न करना, ताले, और हैंडल.

गुणवत्ता नियंत्रण

आयामी सटीकता: सत्यापित करें कि आयाम डिजाइन विनिर्देशों से मेल खाते हैं.

कार्यक्षमता परीक्षण: टेस्ट ओपनिंग/क्लोजिंग लचीलापन और सीलिंग प्रदर्शन.

गुणवत्ता नियंत्रण प्रक्रिया: हर विस्तार में उत्कृष्टता सुनिश्चित करना

कच्चे माल से लेकर तैयार उत्पादों तक, हम हर दरवाजा और खिड़की उच्चतम मानकों को पूरा करने के लिए एक कठोर बहु-चरण गुणवत्ता नियंत्रण प्रक्रिया को लागू करते हैं.

सटीक निरीक्षण और सख्त जाँच के माध्यम से, हम सुरक्षित वितरित करते हैं, टिकाऊ, और हमारे ग्राहकों के लिए सौंदर्यवादी रूप से मनभावन दरवाजे और खिड़कियां.

कच्चा माल निरीक्षण

- एल्यूमीनियम प्रोफाइल: ताकत और संक्षारण प्रतिरोध सुनिश्चित करने के लिए मिश्र धातु रचना और सतह उपचार की जाँच करें.

- पैनलों: विरूपण के लिए निरीक्षण करें, दरारें, बनावट, और कीट क्षति या क्षय जैसे दोष.

- काँच: खरोंच के लिए निरीक्षण करें, बबल, और आयामी विचलन.

हार्डवेयर ऐसेसोरिज: चेक सामग्री, सतह खत्म, और कोई जंग या विरूपण सुनिश्चित करने के लिए कार्यक्षमता.

उत्पादन प्रक्रिया निरीक्षण

- आयामी सटीकता: आयामों को मापने के लिए सटीक उपकरण का उपयोग करें, यह सुनिश्चित करना सहिष्णुता के भीतर है.

- विधानसभा गुणवत्ता: संयुक्त जकड़न का निरीक्षण करें, हार्डवेयर स्थापना सटीकता, और चिकनी संचालन.

- प्रक्रिया संस्था: सत्यापित करें कि प्रत्येक चरण मानक प्रक्रिया आवश्यकताओं को पूरा करता है, उत्पादन स्थिरता सुनिश्चित करना.

समाप्त उत्पाद निरीक्षण

- उपस्थिति की जांच: सतह की गुणवत्ता का निरीक्षण करें, रंग, ग्लोस, और कोई दोष सुनिश्चित करने के लिए सपाटता.

कार्यक्षमता जांच: टेस्ट ओपनिंग/क्लोजिंग लचीलापन, ताला कार्यक्षमता, और हार्डवेयर चिकनाई. - सीलिंग परीक्षण: साउंडप्रूफिंग और थर्मल इन्सुलेशन मीट स्टैंडर्ड्स को सुनिश्चित करने के लिए सीलिंग प्रदर्शन का निरीक्षण करें.

सतत गुणवत्ता

अंतर्राष्ट्रीय गुणवत्ता मानकों को सुनिश्चित करने और पर्यावरणीय प्रभाव को कम करने के लिए शीर्ष स्तरीय आपूर्तिकर्ताओं से पर्यावरण के अनुकूल सामग्री का उपयोग करना.

परिशुद्धता उत्पादन

हमारा एकीकृत कारखाना, उन्नत प्रौद्योगिकी से लैस, बड़े पैमाने पर परियोजनाओं के लिए कुशल उत्पादन और सटीक वितरण सुनिश्चित करता है.

पूर्ण-चक्र समर्थन

डिजाइन परामर्श से लेकर बिक्री के बाद के समर्थन तक, हम अपने ग्राहकों के लिए एक सहज अनुभव सुनिश्चित करने के लिए एक-स्टॉप समाधान प्रदान करते हैं.

प्रत्यक्ष मूल्य

हमारे इन-हाउस कारखाने से प्रत्यक्ष उत्पादन बिचौलियों को समाप्त करता है, लागत प्रभावी और अनुकूलित समाधान प्रदान करना.