Windows and doors are essential in every building, adding beauty, security, and functionality. But have you ever wondered how they are made? The manufacturing process involves precision, technology, and craftsmanship, from raw materials to the final installation-ready products.

Below, we’ll walk you through the complete window and door manufacturing process, answer common questions like how window frames are manufactured and what materials are used, and include details on specialised processes like the aluminium window manufacturing process.

Raw Materials for Windows and Doors

Frame Materials

The choice of material for window and door frames significantly influences their durability, maintenance requirements, and thermal performance. Common materials include:

- Aluminium

Known for its strength, lightweight nature, and corrosion resistance, aluminium is a popular choice, especially in modern architecture.

- UPVC (Unplasticized Polyvinyl Chloride)

This material offers excellent thermal insulation, low maintenance, and affordability, making it a common choice for residential applications.

- Wood

Valued for its natural aesthetics and insulating properties, wood requires regular maintenance to prevent decay and insect infestation.

- Composite Materials

Combining materials like wood and aluminium or UPVC and aluminium, composites aim to leverage the advantages of each constituent.

Glazing Materials

Glass is the primary glazing material used in windows and doors. Types of glass include:

- Float Glass

The most common type, produced by floating molten glass on a bed of molten tin to create uniform thickness and smooth surfaces.

- Tempered Glass

Heat-treated to increase strength; when broken, it shatters into small, blunt pieces, reducing injury risk.

- Laminated Glass

Consists of two or more glass layers bonded with an interlayer, offering enhanced security and sound insulation.

Coated to reflect infrared and ultraviolet rays, improving energy efficiency.

Window Fabrication: Step-by-Step Process

The term window fabrication encompasses the entire process of creating windows, from raw materials to finished products. Let’s explore the general steps involved:

Design and Specification

The process begins with detailed designs, specifying dimensions, materials, glazing types, and hardware. Computer-Aided Design (CAD) software is often used to ensure precision.

Material Preparation

- Frame Profiles

Depending on the chosen material (aluminium, UPVC, wood), profiles are extruded or cut to size.

- Glass Cutting

Large glass sheets are cut to the required dimensions using automated cutting tables.

Frame Assembly

- Aluminium Frames

Profiles are joined using mechanical fasteners or welding. Thermal breaks may be added to improve insulation.

- UPVC Frames

Profiles are welded at corners using heat fusion, creating a strong, seamless joint.

- Wooden Frames

Components are joined using traditional woodworking joints, adhesives, and mechanical fasteners.

Surface Treatment

- Aluminium

Frames may undergo anodising or powder coating for enhanced durability and aesthetics.

- Wood

Frames are sanded, stained, or painted, and sealed to protect against moisture and pests.

Glazing Installation

Glass panes are fitted into the assembled frames, secured with glazing beads, gaskets, and sealants to ensure airtightness and water resistance.

Hardware Installation

Locks, handles, hinges, and other hardware components are installed, ensuring functionality and security.

Quality Control

Appearance Check: Ensure surfaces are flawless and colors are consistent.

Dimensional Accuracy: Verify that dimensions match design specifications.

Functionality Test: Test opening/closing flexibility and sealing performance.

How Are Window Frames Manufactured?

Focusing on the question “How are window frames manufactured?”, the process varies based on the material:

Aluminium Window Manufacturing Process

The aluminium window manufacturing process involves:

- Extrusion: Aluminium billets are heated and forced through dies to create profiles.

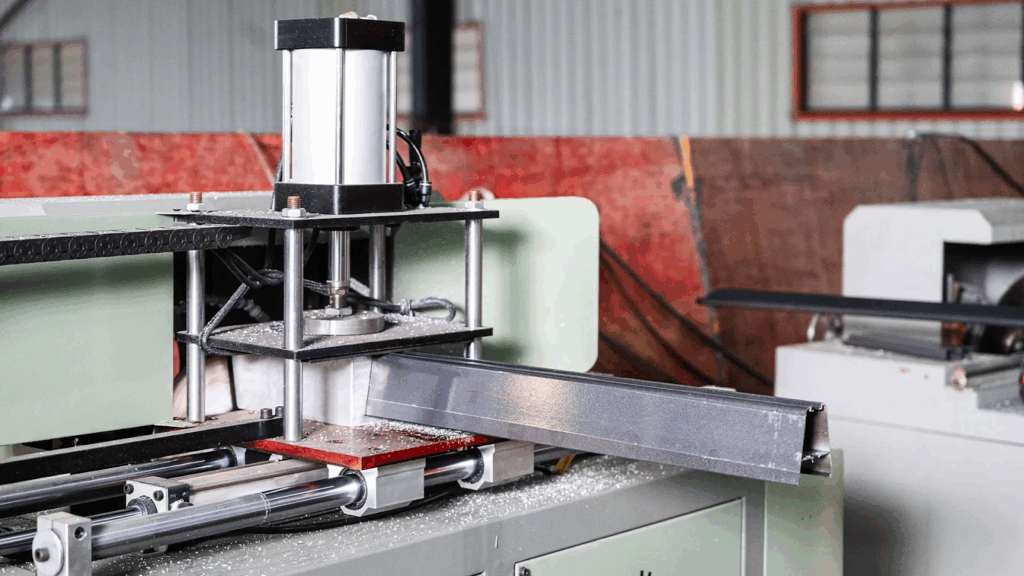

- Cutting: Profiles are cut to the required lengths using precision saws.

- Machining: Holes and slots are machined for hardware installation.

- Assembly: Profiles are joined using mechanical fasteners, with thermal breaks added as needed.

- Surface Treatment: Frames are anodised or powder-coated for protection and aesthetics.

UPVC Window Frame Manufacturing

The process includes:

- Extrusion: UPVC granules are melted and extruded into profiles.

- Cutting: Profiles are cut to size.

- Reinforcement: Steel reinforcements are inserted into profiles for added strength.

- Welding: Corners are welded using heat fusion.

- Cleaning: Excess material from welding is cleaned off.

Wooden Window Frame Manufacturing

Steps include:

- Selection: High-quality timber is selected and seasoned.

- Cutting and Shaping: Timber is cut and shaped into profiles.

- Assembly: Components are joined using adhesives and mechanical fasteners

Door Manufacturing Process

Doors undergo a similar but slightly distinct manufacturing process depending on their type—solid wood, hollow-core, uPVC, aluminium, or composite.

Material Preparation

- Wood

Timber is seasoned and cut to dimensions. For engineered doors, thin veneers are layered over solid cores.

- Aluminium or uPVC

Profiles are extruded similarly to window frames.

- Glass Doors

Typically use tempered or laminated glass for strength and safety.

Frame and Panel Assembly

- Wooden door panels are glued, clamped, and sometimes dowelled or tenoned together.

- Hollow-core doors have internal structures (honeycomb, solid core, or foam) between two outer skins.

- Aluminium and uPVC doors involve mechanical joining or welding of profiles.

Surface Treatment

- Wooden doors may be varnished or painted.

- Aluminium may be powder coated or anodized.

- uPVC is inherently colored during the extrusion process.

Hardware and Finishing

- Locksets, hinges, handles, and vision panels are added.

- Thresholds, seals, and closers may also be installed.

- Each door undergoes final inspection for smooth operation and finish quality.

Conclusion

The manufacturing process of windows and doors is a multi-stage operation that combines precision engineering, material science, and craftsmanship. Whether it’s an elegant timber-framed French window or a modern aluminium sliding door, each unit undergoes a rigorous process to ensure quality, safety, and aesthetics.

By understanding how window frames are manufactured, the raw materials for windows, and the glass window manufacturing process, customers and professionals alike can make informed decisions. The integration of automated technologies in the aluminium window manufacturing process and beyond is reshaping the industry, making products more reliable and efficient than ever before.