The world of modern architecture increasingly relies on sleek, टिकाऊ, and energy-efficient materials — and few can match the versatility and performance of aluminum. Behind every elegant facade or minimalist interior glass door lies a meticulous process led by professional aluminum window manufacturers and aluminum door manufacturers.

From the early stages of design to the final installation, each step requires precision engineering, उन्नत प्रौद्योगिकी, and expert craftsmanship. इस आलेख में, we’ll take you inside the entire process — showing how top manufacturers transform raw aluminum into architectural masterpieces that enhance buildings around the world.

Understanding the Role of an Aluminum Window and Door Manufacturer

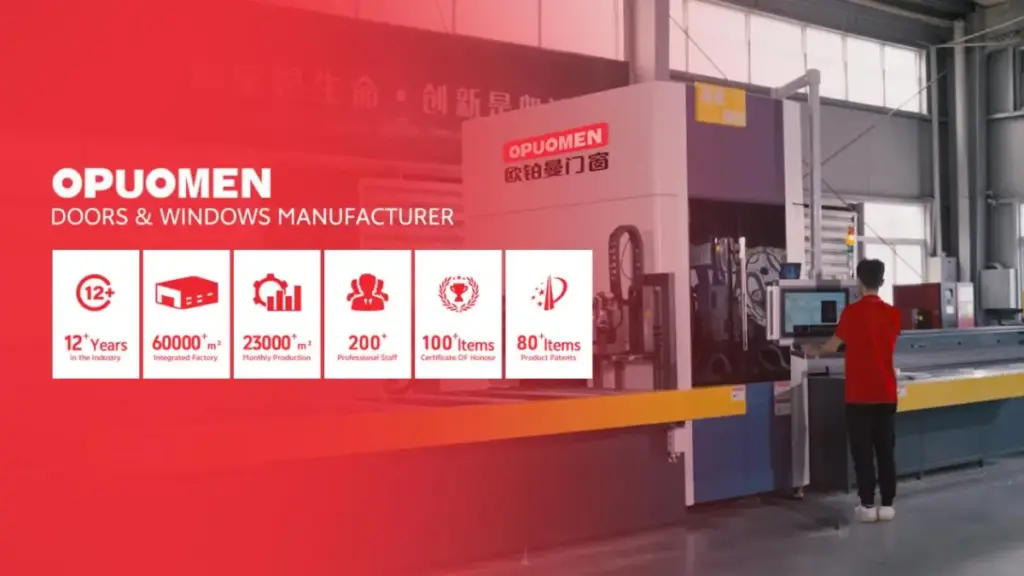

An aluminum window manufacturer is more than just a fabricator — they are solution providers who merge architectural aesthetics with engineering performance. The process begins with understanding client requirements, whether for residential, व्यावसायिक, or industrial projects.

Professional manufacturers design customized systems that meet specific thermal, acoustic, and structural needs. They balance form and function, ensuring every product complements modern architectural trends while meeting stringent building standards.

उसी प्रकार, an aluminum door manufacturer focuses on creating systems that provide security, इन्सुलेशन, और दृश्य अपील. Whether it’s a sliding patio door, a folding system, or a grand entrance design, each product must combine elegance with long-term durability.

कदम 1: Concept and Design Development

Every great aluminum window or door begins with a concept. Architects and clients collaborate with manufacturers to define dimensions, styles, and functional requirements.

Advanced 3D modeling and CAD (कंप्यूटर एडेड डिजाइन) software are used to visualize how the final product will integrate into the building structure. इस स्तर पर, engineers consider factors like wind load, water resistance, इन्सुलेशन, और स्थिरता.

उदाहरण के लिए, modern projects often demand energy-efficient glazing systems. A professional aluminum window manufacturer ensures that their designs support double or triple glazing, लो-ई ग्लास, and thermally broken frames to reduce heat transfer.

कदम 2: Material Selection and Quality Control

The quality of aluminum directly influences the performance and lifespan of the final product. High-grade aluminum alloys, आम तौर पर 6063-T5 or T6, are used for extrusion because of their strength, संक्षारण प्रतिरोध, and formability.

Before उत्पादन begins, the raw materials undergo rigorous testing to ensure consistency in hardness, tensile strength, and chemical composition. A reliable aluminum door manufacturer also performs surface treatment processes such as anodizing, powder coating, or electrophoresis — not only to enhance appearance but also to protect against oxidation and wear.

Environmental sustainability is another important consideration. Many leading manufacturers now use recycled aluminum and eco-friendly coating materials to align with green building standards.

कदम 3: Extrusion and Frame Production

The extrusion process transforms aluminum billets into precise profiles that form the structure of windows and doors. In this stage, the heated billet is forced through a die under high pressure to create complex shapes that match the design specifications.

Once extruded, the profiles are cooled, straightened, and cut to exact lengths. The accuracy of this process ensures that all frames fit together seamlessly during assembly.

A professional aluminum window manufacturer will maintain strict dimensional tolerances, guaranteeing consistency across all batches. This is critical, especially for large-scale commercial projects where hundreds of windows and doors must align perfectly.

कदम 4: Surface Treatment and Finishing

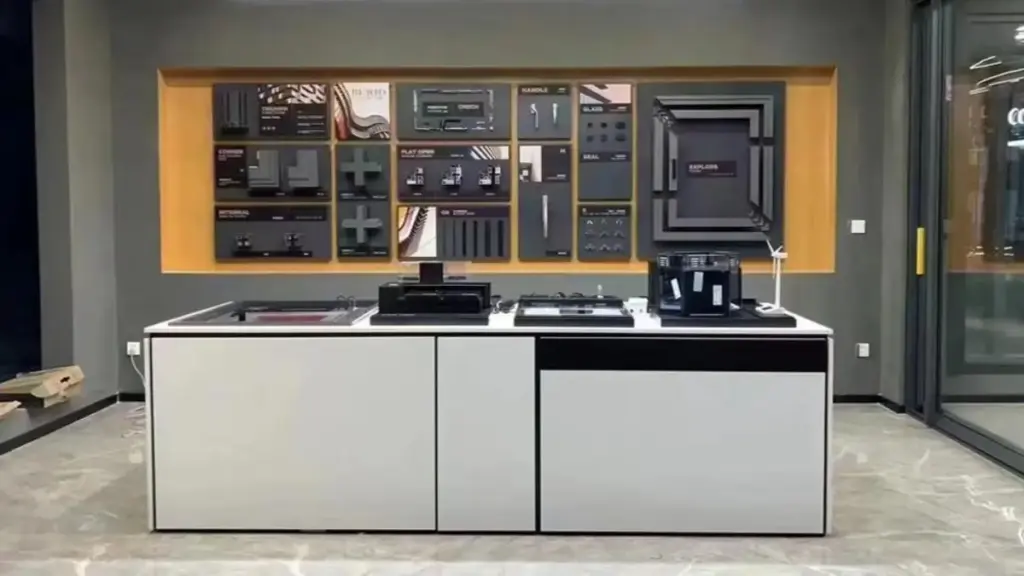

Finishing gives aluminum windows and doors their aesthetic and functional characteristics. Powder coating, एनोडाइजिंग, and wood grain transfer finishes are the most common methods used today.

- Powder coating provides a smooth, durable surface in any RAL color, ideal for modern architectural designs.

- Anodizing enhances corrosion resistance and gives the frame a metallic sheen — perfect for coastal or industrial environments.

- Wood grain finishes allow aluminum door manufacturers to offer products that mimic the warmth of wood while maintaining aluminum’s durability.

Each finish is carefully inspected for color uniformity, thickness, and adhesion to ensure long-lasting performance.

कदम 5: Precision Fabrication and Assembly

After finishing, the profiles move to the fabrication stage, where cutting, ड्रिलिंग, and assembling take place. Advanced CNC machinery ensures precision cutting angles and joint connections.

Rubber gaskets, थर्मल ब्रेक, and insulation strips are integrated to enhance thermal and acoustic performance. Hardware components — such as hinges, संभालती है, and locking systems — are also added, ensuring that every product meets performance and safety standards.

For an aluminum window manufacturer, this phase is crucial. Small inaccuracies can affect the sealing, alignment, and long-term performance of the product. इसलिए, continuous quality checks are performed throughout assembly to ensure reliability and consistency.

कदम 6: Glass Installation and Performance Testing

काँच installation is not just about aesthetics — it directly impacts insulation, सुरक्षा, और ऊर्जा दक्षता. Double or triple-glazed units are commonly used, filled with argon gas to minimize heat transfer.

Each window and door undergoes multiple performance tests, including:

- Air tightness testing to ensure there is no air leakage.

- Water penetration testing to verify resistance against heavy rainfall.

- Wind load testing to confirm structural integrity under pressure.

Reputable aluminum door manufacturers and aluminum window manufacturers often have in-house laboratories for these tests, ensuring compliance with international standards such as ASTM, EN, or AS/NZS.

कदम 7: Packaging, Logistics, and Delivery

After passing quality inspections, the finished products are carefully packaged to prevent scratches or damage during transportation.

Manufacturers work closely with logistics partners to optimize delivery times, whether for local installations or international export. Professional packaging — using foam protection, film wrapping, and wooden crates — ensures that windows and doors arrive at the site in perfect condition.

This final step marks the completion of a long and precise journey — from concept to creation to customer.

The Advantage of Working with a Professional Aluminum Window Manufacturer

Choosing the right manufacturing partner can make or break a construction project. A professional aluminum window manufacturer or aluminum door manufacturer doesn’t just deliver products — they provide complete system solutions, from technical consultation to after-sales support.

Key advantages include:

- अनुकूलन: Tailored solutions for unique architectural requirements.

- Consistency: Strict quality control at every stage.

- Efficiency: Streamlined production and fast delivery times.

- Innovation: Continuous development of energy-saving and sustainable systems.

Whether for residential high-rises, वाणिज्यिक भवन, या लक्जरी विला, professional manufacturers play a crucial role in shaping modern architecture with precision-engineered aluminum systems.

अंतिम विचार

The process of producing aluminum windows and doors is a perfect blend of technology, craftsmanship, और नवाचार. Each step — from design and material selection to extrusion, परिष्करण, and delivery — reflects the dedication and expertise of the aluminum window manufacturer behind the product.

As the demand for sustainable, कुशल ऊर्जा, and visually appealing architectural materials grows, aluminum will continue to dominate the building industry. Partnering with a trusted aluminum door manufacturer ensures that every project benefits from the highest standards of quality, सौंदर्यशास्र, and performance — turning architectural vision into lasting reality.